Ultra-High Molecular Weight Polyethylene (UHMWPE) dock fender pads are specialized marine components designed to absorb impact energy and protect both vessels and docking structures during

The main differences between Ultra-High Molecular Weight Polyethylene (UHMWPE) sheets and High-Density Polyethylene (HDPE) sheets lie in their molecular structure, mechanical properties, and applications. Below is a detailed comparison:

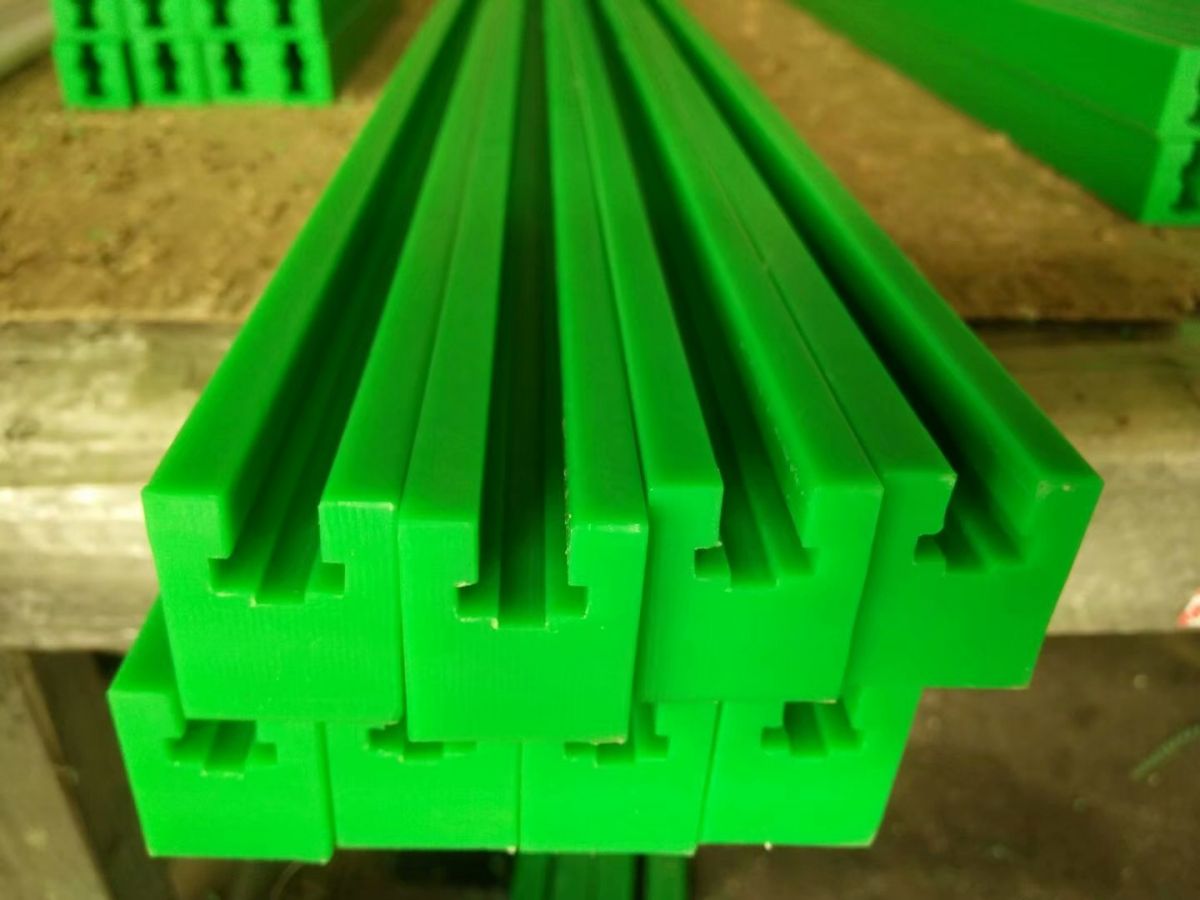

The production process of UHMWPE (Ultra-High Molecular Weight Polyethylene) machined parts involves specialized techniques due to the material’s unique properties—extremely high molecular weight, low melt flow, and

1. Material Properties 2. Hygiene & Maintenance 3. Durability & Lifespan 4. Best Use Case

Polyethylene (PE) crane outrigger pads, typically made from UHMWPE (Ultra-High Molecular Weight Polyethylene) or HDPE (High-Density Polyethylene), serve critical roles in stabilizing and distributing the load of cranes

Ultra-High Molecular Weight Polyethylene (UHMWPE) liners are widely used across industries due to their exceptional wear resistance, low friction, and impact strength. Below are the