The production process of UHMWPE (Ultra-High Molecular Weight Polyethylene) machined parts involves specialized techniques due to the material’s unique properties—extremely high molecular weight, low melt flow, and high abrasion resistance. Below is a step-by-step breakdown of the manufacturing process:

1. Material Selection & Forming

- Raw Material: UHMWPE is supplied as compression-molded sheets, rods, or blocks (since it cannot be melted and injection-molded like HDPE).

- Manufacturing Methods for Blanks:

- Compression Molding: UHMWPE powder is heated and pressed into sheets or blocks under high pressure.

- Ram Extrusion: Used for producing rods or tubes by forcing melted UHMWPE through a die.

2. Machining UHMWPE Parts

Due to its high viscosity and low thermal conductivity, UHMWPE requires specific machining techniques:

A. Cutting & Sawing

- Tools: Carbide-tipped or high-speed steel (HSS) blades with sharp, polished edges (to prevent material sticking).

- Methods:

- Band Saws / Circular Saws – For rough cutting sheets or blocks.

- Waterjet Cutting – Preferred for complex shapes (no heat generation).

- Laser Cutting (Limited Use) – Possible but may cause localized melting.

B. Drilling & Milling

- Tool Requirements:

- Low rake angle (to reduce friction).

- High cutting speed with low feed rate (prevents material deformation).

- Cooling: Air or water cooling is recommended to avoid overheating.

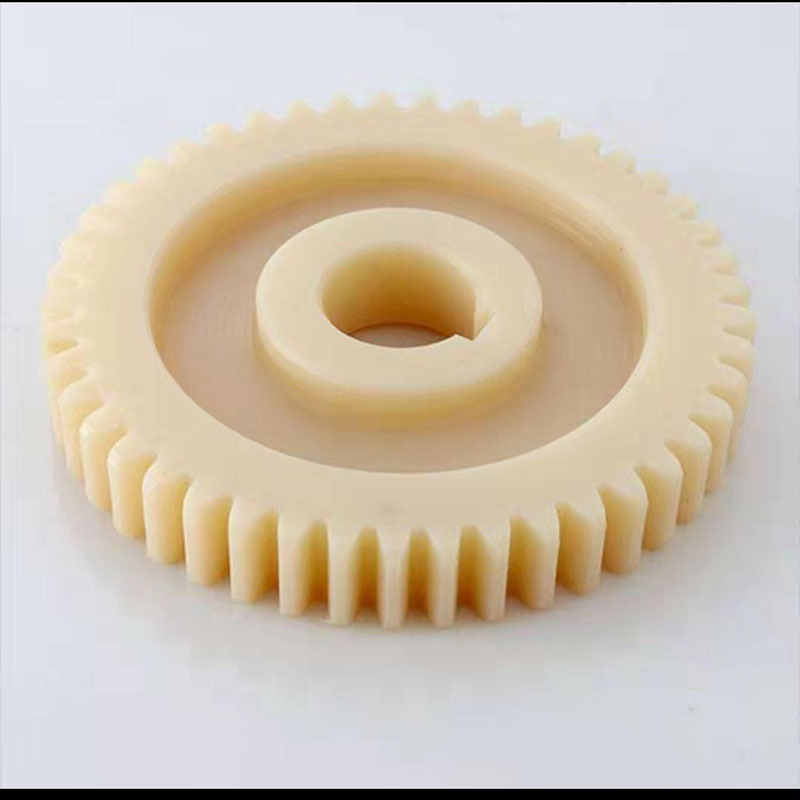

C. Turning (Lathe Work)

- Used for producing cylindrical parts (e.g., bushings, rollers).

- Tool Tips: Carbide inserts with sharp edges to avoid material “gumming up.”

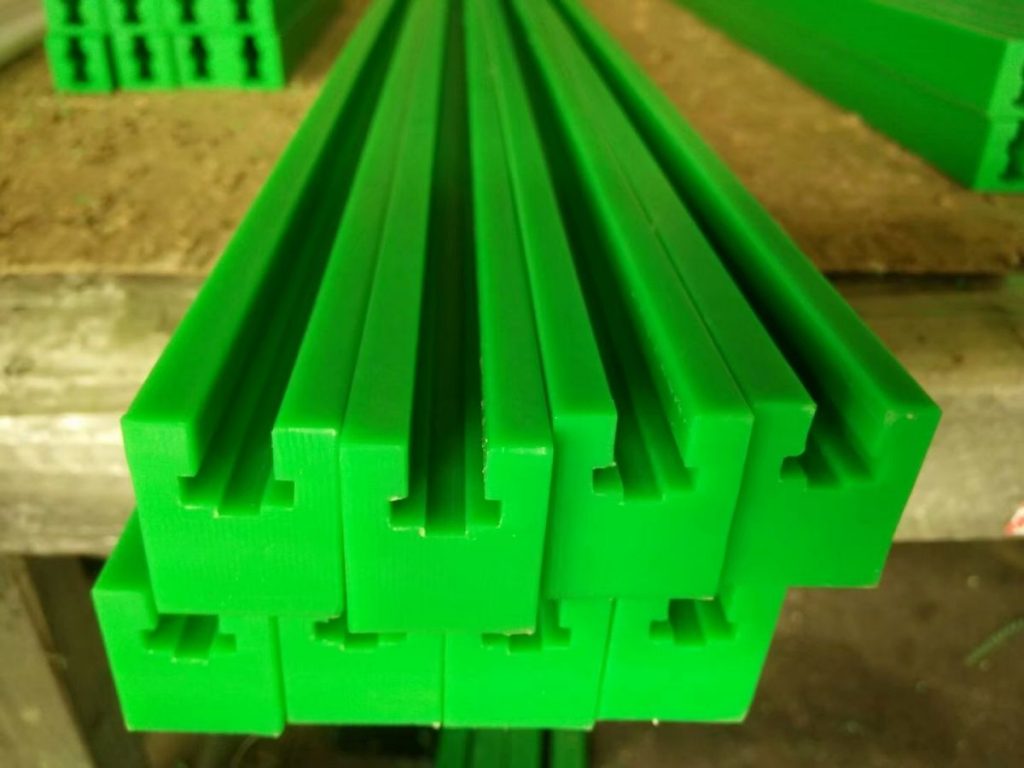

D. CNC Machining

- Suitable for high-precision parts (e.g., medical implants, wear strips).

- Key Considerations:

- Minimize heat buildup (prevents warping).

- Use sharp, polished cutters (reduces burrs).

3. Finishing Processes

- Deburring: Manual trimming or tumbling to remove sharp edges.

- Surface Smoothing:

- Sanding (with fine-grit abrasives).

- Polishing (for low-friction applications).

- Flame Treatment (Optional): Improves adhesion for bonding/painting.

4. Quality Control & Testing

- Dimensional Checks: Ensures tolerances are met (UHMWPE can expand/contract slightly).

- Wear & Impact Testing: Validates performance in real-world conditions.

5. Assembly & Post-Processing

- Bonding: UHMWPE is difficult to glue, so mechanical fastening (screws, rivets) or special adhesives (e.g., epoxy for plastics) are used.

- Welding (Limited Use):

- Hot Gas Welding – Possible but challenging due to low melt flow.

- Butt Fusion Welding – Used for joining UHMWPE pipes.

Key Challenges in UHMWPE Machining

- Heat Buildup → Can cause warping or melting.

- Material Flexibility → Requires sharp tools to avoid deformation.

- Low Thermal Conductivity → Cooling is critical.

Applications of Machined UHMWPE Parts

Medical Implants (joint replacements).

Wear Strips & Liners (conveyors, chutes).

Bushings & Bearings (low friction, self-lubricating).

Marine Components (dock fenders, boat bumpers).